Timber framing has been a popular construction method for centuries, offering strength, durability, and a warm, natural aesthetic. Today, this timeless technique continues to capture the hearts of architects, builders, and homeowners alike. But how can you make the most of timber frame materials for your project?

In this comprehensive guide, we’ll walk you through the essentials of timber frame construction, selecting suitable wood species, moisture management, joinery methods, sustainable sourcing, and more.

Key Takeaways

- Understanding timber frame construction involves understanding the components, joints, and carpentry methods used.

- Douglas Fir is a popular choice for timber framing in North America, accounting for approximately 60% of timber frames in the region.

- Adhering to building codes is necessary for a timber-framed structure’s safety, stability, and longevity.

Understanding Timber Frame Construction

Heavy timber frame construction is a method of building framed structures that use less processed, large dimensional lumber. The joints used in this type of all-timber construction can include lap jointing and pegged mortise & tenon joints.

Vertical, horizontal, and sloping wood members are employed in heavy timber buildings to create a robust and secure structure. Several timber framing options are available, including traditional half-timbered construction, post and beam construction, lintel style, variations of half-timbering, and ridge-post framing, each with unique construction details.

Diagonal bracing is a crucial component in timber framing, as it prevents “racking” or movement of structural vertical beams or posts in wood structures. The infill, a nonstructural building material, is used to fill the gaps between the structural components of a timber frame. Once you grasp these essential components, you will be better prepared to decide on the most suitable timber framing approach for your project.

Components of a Timber Frame

A timber frame consists of posts, wooden beams, braces, and other structural elements that construct a robust and secure structure.

Various timber framing options, such as traditional half-timbered construction, post and lintel style, post and beam, and ridge-post framing, allow for customization and adaptability to different architectural styles and preferences.

Choosing suitable joinery techniques and comprehending the components of a timber frame allows you to construct a structurally sound and visually appealing building that lasts for generations.

Glossary of Terms

Navigating the world of timber framing requires a good grasp of the terminology used in this construction method.

Terms related to timber framing include those related to construction, species characteristics, and joinery. Understanding what timber refers to in this context is essential for mastering the art of timber framing.

Key terms associated with timber framing construction include:

- Timber: A squared-off length of wood that is used structurally.

- Post: The primary vertical timbers.

- Beam: The primary horizontal support timbers.

- Rafters: Series of timbers that are used to support roofs.

- Brace: A diagonal piece of timber used to support beams.

- Joist: Horizontal timbers used to support floors and ceilings.

- Gable: The triangular upper part of a wall that connects to a pitched roof.

- Purlin: A purlin is a horizontal roof beam that supports rafters and spans the distance between gable ends.

- Chord: The bottom horizontal timber in a truss.

- Corbel: A bracket that projects from a wall to support a structure above it.

- Mortise: A mortise is a notch, hole, or cut in a piece of wood into which a tenon is fit to join two timbers together. This is the female part of a joint.

- Tenon: A tenon is the cut end of a timber that fits into a mortise to join two pieces of timber together. This is the male part of a joint.

- Collar Tie: A horizontal beam between roof rafters that reduces the spreading or sagging of the rafters.

- Glulam: This type of beam is comprised of layers of 1-inch or 1-1/2 inch boards that are glued together.

- Truss: An assembly of wood members used to create a rigid structure.

- King Post: A truss with a center vertical beam with an angled support beam on each side of the vertical beam.

- Queen Post: A queen post is a truss with two vertical beams that each have an outer angled support beam.

- Joinery: Two or more timbers that are connected. The combined components of a timber frame.

- Rough Sawn: Timber that has not been sanded or textured but is used as originally cut.

Being well-versed in these terms allows informed decision-making throughout your timber framing project.

Selecting Suitable Wood Species for Timber Framing

Selecting the suitable wood species for your timber frame project is crucial, as it impacts your structure’s strength, durability, and cost.

Essential wood characteristics to consider when selecting a timber species for a frame include:

- timber grade

- moisture content

- heart content

- and surface texture.

Grasping the characteristics of the wood species you are thinking of selecting enables you to select the proper material for your project.

Douglas Fir

Douglas Fir is a popular choice for timber framing in North America, accounting for approximately 60% of timber frames in the region. It offers several advantages, such as its strength and stability, as well as minimal cracking and checking. This strong and stable wood species is widely distributed in the Pacific Northwest and other parts of North America.

Reclaimed vs. Freshly Sawn Wood

When you select wood for your timber framing project, understanding the differences between reclaimed and freshly sawn wood is vital.

Freshly harvested and sawn timbers are obtained from living trees, while reclaimed wood was cut in the past and has been weathered for many seasons.

Reclaimed wood offers lower environmental impacts than freshly sawn wood, as it minimizes the demand for newly sourced virgin lumber. However, the cost of reclaimed wood tends to be relatively high compared to newly sawn wood because it is much scarcer.

Freshly sawn wood has a distinct advantage in availability, customization, and consistency compared to reclaimed timber, a finite resource.

Both reclaimed and freshly sawn wood have their unique advantages and drawbacks, with the final choice hinging on your project’s specific needs and priorities.

Moisture Management in Timber Framing

Moisture management is paramount in timber frame construction, as timber and wood products are hygroscopic materials that absorb and release moisture.

If moisture is not managed correctly, it can result in warping, dimensional changes, and decay in the timber.

Additionally, moisture can penetrate deeply into the timber and become trapped, undermining the house’s or building’s structural integrity.

To effectively manage moisture in timber framing, it’s essential to utilize the following techniques and materials:

- Flashing systems

- Drying techniques

- Moisture-resistant materials

- Proper ventilation

The drying process of timber, such as kiln drying, decreases the moisture content of the wood, providing a more stable and reliable material for construction.

Maintaining proper moisture management throughout your timber framing project guarantees the longevity and structural integrity of your building, preserving your investment for the future.

Joinery Methods for Timber Framing

Timber framing employs various joinery methods to create secure and stable connections between structural components, such as:

- Mortise and tenon joints involve the insertion of a tenon (a protruding piece of wood) into a mortise (a corresponding cavity), creating a strong and reliable connection.

- Lap joints involve overlapping two pieces of timber and securing them together with fasteners or adhesives.

- Modern timber connectors: include metal brackets, plates, and screws that provide additional strength and stability to the timber frame.

These joinery methods ensure the structural integrity of the timber frame and beam construction and contribute to its overall strength and durability.

Lap joints, conversely, are achieved by cutting half the thickness of two boards and joining them together, with fasteners in the middle to secure them. Scarf joints are an alternative method, where two plates have a mirror imaged, angled half-lap joint cut on their ends.

Modern timber connectors (such as Beam hangers, Self-tapping screws, Lapped connections, and Roof truss connectors) further enhance the structural soundness of timber framing.

Comprehending and applying these joinery methods allows for creating a robust and enduring timber frame structure tailored to your project’s specific requirements.

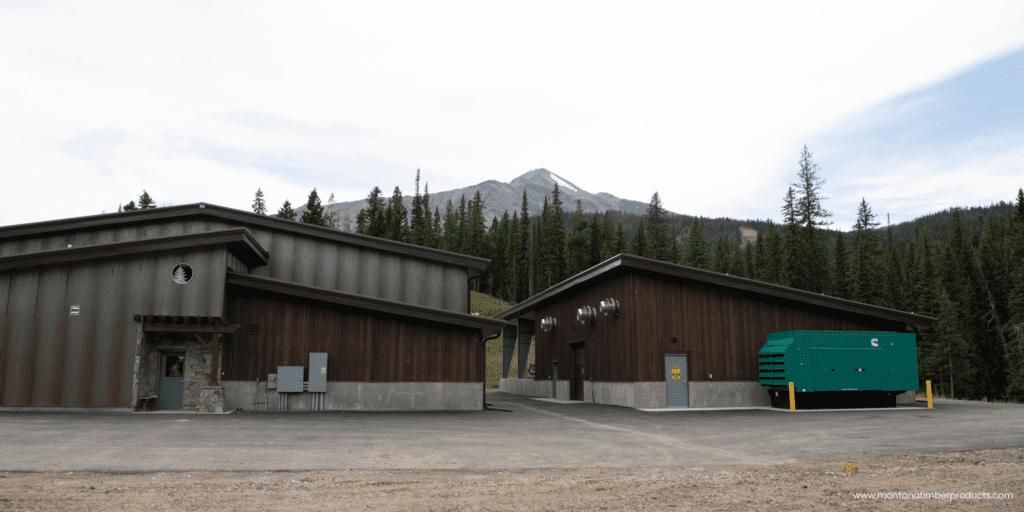

Sustainable Timber Sourcing

Sustainable timber sourcing is an essential consideration when planning your timber framing project. By choosing locally available species, you can decrease the environmental impact of transportation, support local economies, and access a range of species suited to the local climate.

Prioritizing sustainable timber sourcing practices helps lessen your project’s environmental impact while still enjoying the aesthetic and structural advantages of timber framing.

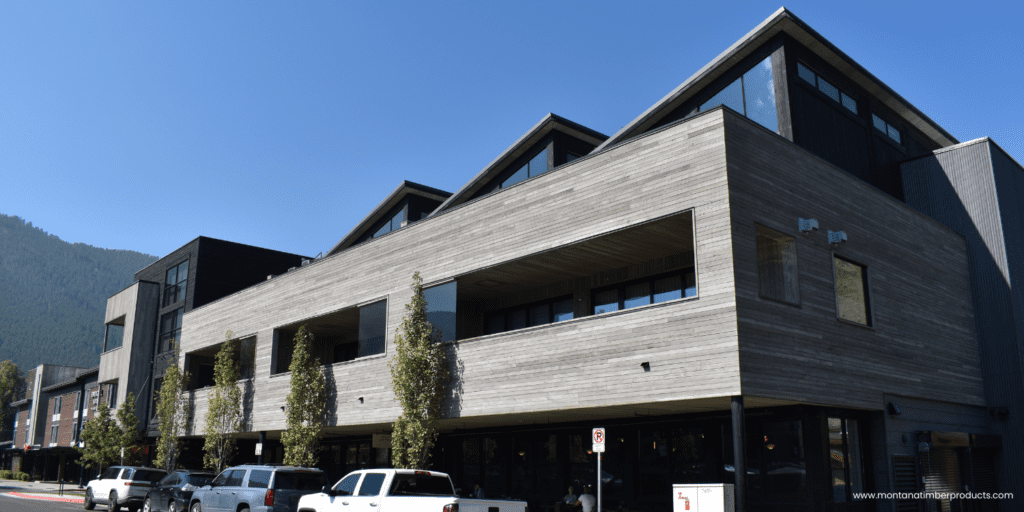

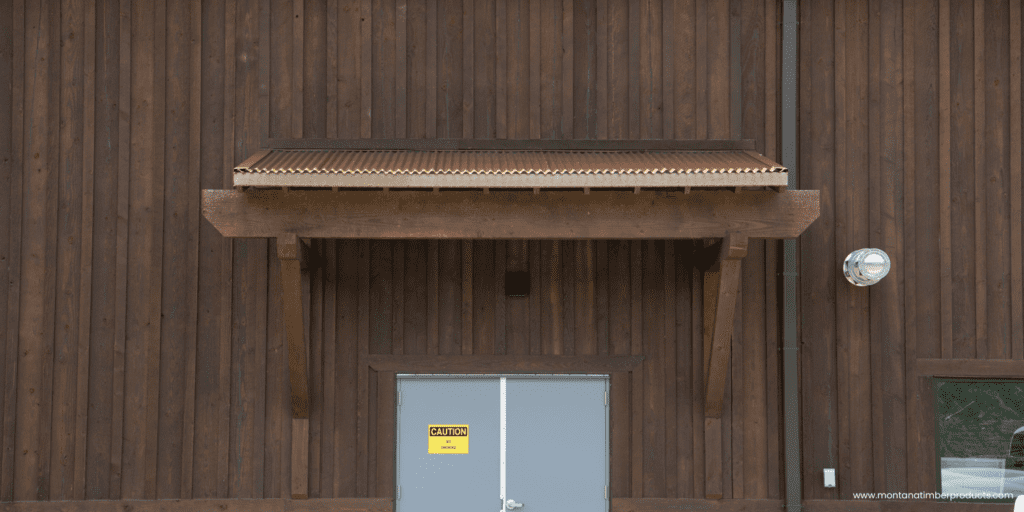

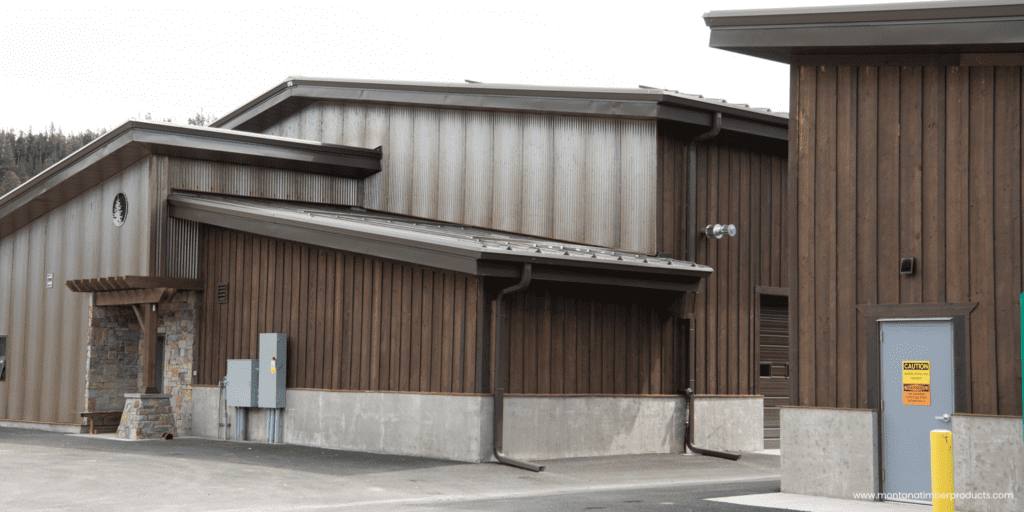

Timber Frame Finishes and Treatments

Various finishes and treatments are available to protect and enhance the appearance of your timber frame structure. Treatments like wood preservers, pressure treating, and repairing decayed areas can protect timber frames from pests, rot, and weather damage.

Different finishes can considerably affect the visual appeal of timber frames. Some options include:

- Varnish or lacquer: These finishes can highlight the natural beauty of the wood and create a glossy finish.

- Stains: Stains can change the color of the wood to coordinate with other elements in the space or achieve a specific aesthetic.

- Oil or wax finishes: These provide a more matte or natural look while still preserving the wood.

As with all natural wood materials offered at Montana Timber Products, we pre-finish our timber frame materials with SEAL-ONCE®.

SEAL-ONCE® is an eco-friendly, ultra-low VOC, water-based stain and sealer for wood that offers high performance and long-lasting protection against water damage.

By forming a flexible, breathable barrier between the wood and the surrounding environment, it stabilizes the material, protecting against water damage and decay for up to 10 years on vertical surfaces and 5 years on horizontal surfaces.

Click the following link to learn more about the Limited-Warranty that comes with material from Montana Timber Products.

Building Codes and Regulations for Timber Framing

Understanding building codes and regulations related to timber framing ensures your project meets safety and structural requirements.

Timber framing falls outside the scope of the International Residential Code (IRC) and may have specific requirements, which can vary by location. It is advisable to consult with local building code offices and timber frame industry standards for guidance on compliance.

Timber frame construction codes may vary depending on the country or region where the structure is built. Some countries have specific requirements for:

- Allowable materials

- Structural design criteria

- Fire resistance standards

- Other factors

Adhering to these codes and regulations is essential for the safety, stability, and longevity of your timber frame structure.

Getting acquainted with the relevant building codes and regulations related to timber framing guarantees that your project, whether residential or commercial buildings, adheres to the highest safety and structural standards, securing your investment and offering peace of mind.

Fire-Resistance

Many municipalities in the United States are adopting new construction codes due to the ever-growing concern of wildfires in the Wildland Urban Interface (WUI). Montana Timber Products has defensive solutions and peace of mind protection when considering exposed timbers in a wildfire-prone building zone.

- Fireline Pressure Treated is fully WUI and IWUI certified.

- FX Lumber Guard XT is Class A Rated and never has to be reapplied.

Both treatments can be applied to the full range of MTP timbers.

Summary

Timber framing offers a unique combination of strength, durability, and aesthetic appeal, making it an ideal choice for various construction projects. By understanding the essentials of timber frame construction, selecting suitable wood species, managing moisture, employing proper joinery methods, sourcing sustainably, and adhering to building codes and regulations, you can create a beautiful, long-lasting structure that stands the test of time.

So, whether you’re planning a cozy cottage or an impressive commercial building, timber framing holds the key to unlocking the full potential of your dream project.

Frequently Asked Questions

What kind of wood is used for timber frames?

Common woods used for timber frames include oak, Douglas Fir, Southern Yellow Pine, Eastern White Pine, Hemlock, West Coast Douglas Fir, Maple, Yellow Birch, White and Red Oak, Cypress, Cedar, Spruce, and others. These varieties are strong and hard timber choices that are generally more plentiful, check less, and emit pleasant scents for years.

What designates lumber as timber?

Timber typically refers to less processed, larger, thicker pieces of wood used in heavy construction and structural applications such as beams and posts.

Are there any disadvantages to using reclaimed wood in timber framing?

Reclaimed timbers are challenging to find because old barns and buildings are finite resources. It’s also limited in customization due to a lack of available sizes. It can also be challenging for projects that require a more consistent aesthetic.

How can I manage moisture in my timber frame structure to ensure its longevity?

Ensure the longevity of your timber frame structure by employing proper moisture management techniques, such as flashing systems, drying techniques, moisture-resistant materials, and ventilation.